A First-Timer's Guide to "Thinking in Thermal": How to Read an Infrared Camera

Update on Nov. 4, 2025, 6:20 p.m.

One user of a pocket-sized thermal camera reported that on the very first day he owned it, he found a hidden electrical outlet that was melting from the inside out. It was an invisible fire hazard that, if left unchecked, could have burned his house down.

Another user, a contractor, was stumped by a client’s buckling hardwood floors. There were no visible signs of water. He pointed his thermal camera at the wall and instantly saw a faint, cold blue line—the signature of a pinhole leak from a pipe spraying water onto the inside of the drywall.

To a beginner, a thermal camera can feel like a toy. You point it at your cat, your coffee mug, or your car engine and see a splash of psychedelic colors. But to a professional—or a very smart homeowner—it’s a diagnostic “sixth sense.” It’s a non-invasive tool that instantly tells you where to look for problems you could never see with your naked eye.

The difference isn’t the tool; it’s the knowledge. The key is learning how to “think in thermal.”

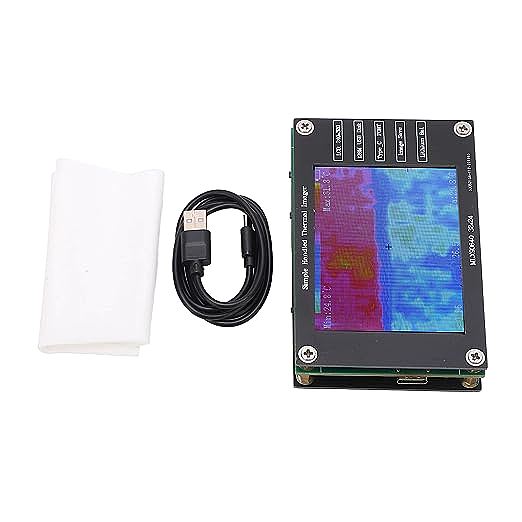

As your guide, we’re going to teach you the core concepts of thermal troubleshooting. We’ll use a high-resolution, pocket-sized device like the Hti-Xintai HT-A2 as our classroom example, not to sell it, but because its specs perfectly illustrate the concepts you need to master.

Lesson 1: You’re Not Seeing “Heat,” You’re Seeing “Differences”

This is the most important lesson. Your eyes see visible light, which is reflective. A thermal camera sees emissive infrared energy.

Here’s what that means in plain English: When you point an IR camera at a wall, you’re not just seeing “a wall.” You are seeing a detailed map of temperature differences. That’s where the magic is.

A new user sees a “cold spot” on their ceiling. A trained user sees a “thermal anomaly” and knows that spot is cold relative to the rest of the ceiling. This is the clue that leads them to ask “Why?” The answer is often a hidden problem: * A cold spot on a ceiling? That’s a sign of missing insulation. * A cold, blooming patch on a wall? That’s the signature of hidden moisture and evaporation. * A hot spot on an electrical breaker? That’s the signature of high resistance—and an imminent fire hazard.

Your thermal camera is a “difference detector.” The colors on the screen (blue for cold, red/white for hot) are just a visual guide to help you spot these differences instantly.

Lesson 2: “Sharpness” — Why 320x240 Resolution is a Game-Changer

When you shop for a thermal camera, you’ll see “Resolution” as the main spec. Many entry-level (or phone-based) cameras have low resolutions, like 80x60. A professional-grade pocket unit like the Hti-Xintai HT-A2 boasts a 320 x 240 IR resolution.

That’s a total of 76,800 pixels.

Why should you care? It’s not just about a “prettier picture.” It’s about safety and accuracy.

Every single pixel on that sensor is an individual thermometer. The more pixels you have, the smaller the thing you can accurately measure from a safe distance.

- Low-Resolution (80x60 = 4,800 pixels): To get an accurate reading on a small electrical breaker, you might have to stand just one foot away. This is impractical and often dangerous.

- High-Resolution (320x240 = 76,800 pixels): With 16 times more pixels, you can stand five or ten feet back and still get a clear, accurate reading on that same small breaker.

More pixels mean you can “see” smaller problems, and you can see them from further away. This high resolution is what allows you to scan an entire wall and spot a single, tiny cold spot that could be a pinhole leak, or scan an entire electrical panel and see that one lug nut is overheating by 15 degrees.

Lesson 3: “Sensitivity” — Detecting the Faint Whisper of a Problem

If resolution is the “sharpness” of your new sense, thermal sensitivity is its “hearing.” This spec is often listed as NETD (Noise Equivalent Temperature Difference). For the HT-A2, it’s 0.07°C.

This means the camera is sensitive enough to detect a temperature difference of just seven-hundredths of a degree.

Your first thought might be, “Why do I need that? I’m looking for a 200°F breaker, not a 0.07°F breeze.”

You need it for the subtle problems. The most destructive issues, like water leaks, don’t shout; they whisper. When water seeps into drywall, it starts to evaporate. This evaporation creates a tiny cooling effect, often less than a single degree.

Your hand will never feel it. Your eyes will never see it. But a high-sensitivity camera sees it as a clear, blooming, blue-purple shape. This is the superpower. It’s what allows a contractor to find that pinhole leak or to prove to a homeowner exactly where their insulation is failing without drilling a single hole.

- Resolution finds the hot problems.

- Sensitivity finds the hidden problems.

Lesson 4: “Context” — Why Two Cameras Are Better Than One

You’ve probably seen thermal images that are just a confusing blob of colors. You think, “Great, something is hot, but… what is it?”

This is why modern cameras like the HT-A2 include a second, built-in visible light camera. The most useful feature for any beginner is image blending (which the HT-A2 calls “Image Coincidence”).

The camera takes a thermal image and a regular photo at the same time. It then overlays the thermal image on top of the visible one. This gives you the “what” and the “where.”

You no longer see a vague hot blob. You see the exact outlet, breaker, or pipe that is overheating. You can see the outline of the wall studs and exactly where the cold spot of missing insulation is between them. For troubleshooting, this context is everything. It removes the guesswork and lets you pinpoint the problem with confidence.

Lesson 5: The “Gotcha” — A Quick, Vital Tip on Emissivity

Your new superpower has one kryptonite: shiny surfaces.

As we learned in Lesson 1, a thermal camera sees emitted heat. But very shiny, reflective surfaces (like polished stainless steel or a mirror) are poor emitters. They act like thermal mirrors.

If you point your camera at a shiny chrome pipe, you’re not seeing the pipe’s temperature. You’re seeing the reflection of your own body heat. This will confuse you to no end.

The Mentor’s Pro-Tip: If you need to get an accurate temperature reading on a shiny, reflective surface, you have to change that surface. The easiest way? Put a small piece of black matte electrical tape on it.

Wait a moment for the tape to match the object’s temperature, then measure the tape. The tape has a very high emissivity (~0.95), meaning it’s an “honest” radiator. The reading you get from the tape will be the true, accurate temperature of the object.

Your First Thermal Hunt: Where to Look

You’ve got the concepts. Now, let’s put them to work. Here is a simple checklist for your first day with a thermal imager.

-

1. The Electrical Panel (The Money-Maker):

With all due caution (or hiring an electrician), scan your home’s breaker panel. All breakers should be roughly the same temperature. If you see one that is glowing white-hot compared to its neighbors, you have found a high-resistance fault. This is the exact problem that saved one user a fortune. This alone can justify the cost of the tool. -

2. Walls, Windows, and Doors (The Energy-Saver):

On a very cold or very hot day, scan the seams where your walls meet the ceiling and floor. Look at your window frames and door seals. The faint blue (in winter) or yellow (in summer) lines you see are drafts. This is literally a visual map of where your energy bill is leaking out. -

3. Below Sinks and Showers (The Leak-Finder):

Scan the wall behind your shower and the ceiling below your upstairs bathroom. Even if the drywall is perfectly clean and dry to the touch, a high-sensitivity camera will pick up the faint, cold signature of a slow, hidden leak. -

4. The Fun Stuff (The “Sixth Sense”):

Now you can have fun. See which cars in a parking lot were driven recently. Find your pet in a pitch-black room. You’re not just a homeowner or a contractor anymore—you’re a thermal detective.

A high-resolution, high-sensitivity thermal camera isn’t just a tool. It’s a new way of seeing the world. It empowers you to find problems, save money, and prevent disasters, all by translating the invisible language of heat into a picture you can finally understand.