PerfectPrime IR281 Thermal Imager: Unveiling the Invisible World of Heat with 32k Pixel Resolution

Update on April 24, 2025, 1:34 p.m.

We exist in a world bathed in light we can see, but that’s only a tiny fraction of the story. Beyond the familiar rainbow of colors lies a vast spectrum of electromagnetic radiation, much of it invisible to our eyes. Among the most fascinating of these hidden realms is the world of infrared (IR) – the language of heat itself. Every object around us, from the coldest ice to the hottest flame, constantly emits this invisible energy, broadcasting its thermal state. Imagine if we could perceive this hidden dimension. What secrets would it reveal about our homes, our machines, our environment?

Remarkably, we can see this world, thanks to the marvel of thermal imaging technology. And tools like the PerfectPrime IR281 Infrared (IR) Thermal Imager are bringing this extraordinary capability, once confined to high-tech labs and military applications, into the hands of professionals and curious individuals eager to understand their surroundings on a deeper level.

The Accidental Discovery That Revealed Heat’s True Nature

Our journey into seeing heat arguably began over two centuries ago. In 1800, the astronomer Sir William Herschel was experimenting with prisms, splitting sunlight into its constituent colors to measure the temperature of each. To his surprise, he found that a thermometer placed beyond the red end of the visible spectrum, where no light was visible, registered the highest temperature. He had stumbled upon invisible “calorific rays” – what we now know as infrared radiation. Herschel had inadvertently opened a window onto the thermal universe.

Decoding the Language of Heat: How We ‘See’ Infrared

So, what is this infrared radiation? Think of it as light, but with wavelengths longer than visible red light. Every object above the absolute coldest temperature possible (absolute zero, or $-459.67^{\circ}$F / $-273.15^{\circ}$C) emits IR radiation simply because its atoms are in constant motion. The hotter the object, the more vigorously its atoms vibrate, and the more intense the IR radiation it emits.

A thermal imager, at its heart, is a sophisticated detector designed to capture this specific type of energy. Many modern thermal cameras, likely including devices like the IR281, employ an array of microscopic sensors called a microbolometer array. Each tiny sensor in this grid absorbs incoming IR radiation, which causes its temperature to change slightly. This temperature change alters the sensor’s electrical resistance. The camera’s electronics measure these changes across the entire grid, translating the pattern of varying IR intensities into a digital image – a thermogram. In this ‘heat map,’ different colors or shades of gray are assigned to different temperature ranges, allowing us to instantly visualize the thermal landscape.

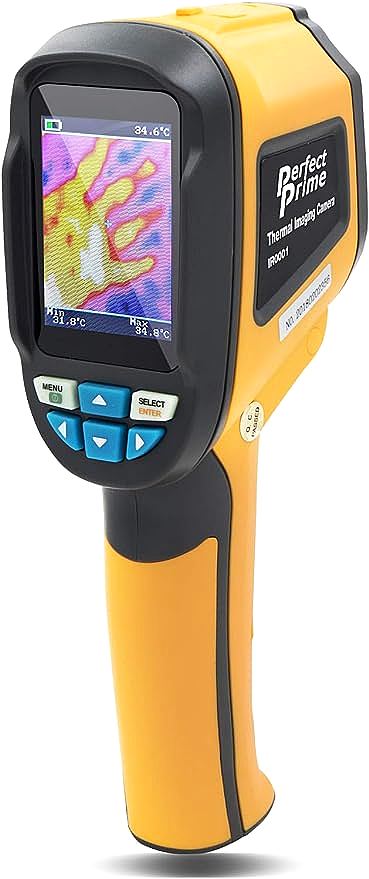

A Window into the Thermal World: The PerfectPrime IR281

The PerfectPrime IR281 is a tangible example of this technology packaged into a handheld device. It’s designed not just to see heat, but to measure it, providing quantifiable data about the thermal world it observes. But looking at a spec sheet only tells part of the story. Let’s delve into what some of its key capabilities, based on the provided product information, truly mean in the context of understanding and interacting with thermal energy.

Pixels of Heat: Why Resolution Matters (206x156)

The IR281 is specified as having a thermal resolution of $206 \times 156$ pixels. This means its sensor array is a grid with 206 columns and 156 rows, totaling 32,136 individual detection points. Think of these like the pixels in your digital camera, but instead of capturing visible light, each one captures the infrared energy from a small spot in the scene.

Why is this important? Just as higher resolution in a regular camera gives you a sharper, more detailed photograph, higher thermal resolution allows you to see finer thermal details. A low-resolution thermal image might show a general warm area on a wall, but a higher-resolution image, like that potentially offered by the IR281’s 32k pixels, could reveal if that warmth is a diffuse patch indicating missing insulation, or a distinct, sharp line suggesting an air leak along a stud. It’s the difference between seeing a blurry shape and identifying a specific feature. This ability to resolve fine spatial detail is critical for pinpointing the exact location of a small overheating electrical connection or distinguishing between multiple closely spaced thermal anomalies.

From Freezing Cold to Sizzling Hot: The Versatility of Range (-40°F to 626°F)

The specified temperature measurement range of the IR281, -40°F to 626°F (-40°C to 330°C), defines the breadth of thermal conditions it’s designed to handle. This isn’t just about reading extreme numbers; it’s about versatility. Imagine needing to check both the sub-zero conditions inside a commercial freezer and the elevated temperatures of components in an industrial process or a hard-working electrical panel.

A wide temperature range ensures the sensor isn’t overwhelmed (saturated) by very high IR emissions, nor unable to register the faint emissions from very cold objects. This capability allows a single tool to be potentially applied across diverse diagnostic tasks – from verifying HVAC system performance across hot and cold cycles to inspecting automotive components or moderate-temperature manufacturing processes, ensuring its utility in various professional and home inspection scenarios.

Sensing the Subtle: The Power of High Sensitivity (0.065°C)

Perhaps one of the most critical, yet sometimes overlooked, specifications is thermal sensitivity, often expressed as NETD (Noise Equivalent Temperature Difference). The IR281 specifies a sensitivity of 0.065°C. This number represents the smallest temperature difference the camera can reliably distinguish between two points.

Think of it like the dynamic range of your hearing. Some sounds are loud and obvious, but detecting a faint whisper requires keen sensitivity. Similarly, while large temperature differences (like a hot stove) are easy to see, many crucial diagnostic clues involve very subtle thermal variations. A sensitivity of 0.065°C means the camera has the potential to discern temperature differences less than one-tenth of a degree Celsius. This is incredibly important for tasks like:

- Detecting Air Leaks: Cold drafts often create very slight temperature changes on interior surfaces.

- Finding Moisture Intrusion: Wet building materials tend to be slightly cooler than dry ones due to evaporative cooling, a difference high sensitivity can pick up.

- Identifying Insulation Flaws: Inconsistent insulation might only cause minor variations in surface temperature.

Without high sensitivity, these subtle but significant issues might remain completely invisible, even to a thermal imager.

Readings You Can Trust: Understanding Accuracy (±2% or ±2°C)

While seeing thermal patterns is insightful, often you need to know the actual temperature. The IR281’s stated accuracy is ± 2% or ± 2°C (whichever value represents a larger tolerance). This specification gives you a measure of confidence in the numerical temperature readings provided by the camera. If the camera displays a reading of $100^{\circ}$C, an accuracy of $\pm 2^{\circ}$C means the actual temperature is likely between $98^{\circ}$C and $102^{\circ}$C.

This level of accuracy is vital for making informed judgments. Is that electrical wire at $70^{\circ}$C operating normally, or is it dangerously close to its maximum rating? Comparing readings over time to monitor potential degradation also relies on consistent accuracy.

It’s crucial to understand, however, that achieving accurate temperature measurements with any thermal imager in the real world involves more than just the camera’s inherent accuracy. A critical factor is emissivity – a property of a material’s surface that describes how efficiently it emits infrared radiation compared to a perfect emitter (a “blackbody”). Different materials (e.g., shiny metal vs. matte paint vs. human skin) have vastly different emissivities. While the provided source material doesn’t detail emissivity adjustments on the IR281, users of any thermal imager need to be aware that measuring temperature accurately often requires setting the correct emissivity value for the surface being observed, or using known-emissivity reference targets (like electrical tape). Ignoring emissivity can lead to significant errors, regardless of the camera’s stated accuracy.

Beyond Pretty Pictures: Unleashing Radiometric Data

A modern thermal imager can be much more than a device that simply shows you heat patterns. The IR281 is described as capturing radiometric data and storing it, potentially in CSV (Comma Separated Values) format. This is a powerful feature.

“Radiometric” means that the camera doesn’t just create a visual picture; it records the actual estimated temperature value for each and every one of those 32,136 pixels. Imagine the thermal image not just as a picture, but as a detailed spreadsheet of temperature readings overlaid on the scene.

Exporting this data in a format like CSV allows for detailed post-processing and analysis using compatible software (the source mentions compatibility with thermal software and provides free software). This opens up possibilities far beyond on-the-spot assessment:

- Detailed Reporting: Generate comprehensive inspection reports with precise temperature measurements for specific points of interest.

- Off-Site Analysis: Spend less time in potentially hazardous or uncomfortable environments by capturing data quickly and analyzing it thoroughly later.

- Trend Monitoring: Compare radiometric data from the same equipment over time to detect gradual temperature increases that might signal developing problems.

- Precise Diagnostics: Click on any pixel in the saved data using analysis software to get its specific temperature reading, enabling highly targeted investigation.

This capability transforms the thermal imager from a purely visual tool into a quantitative measurement instrument.

Thermal Detective Work: Real-World Applications

When you combine these features – the detailed vision of high resolution, the versatility of a wide temperature range, the subtlety captured by high sensitivity, the confidence of good accuracy, and the analytical power of radiometric data – the PerfectPrime IR281 becomes a potent tool for “thermal detective work”:

- The Energy Leak Hunter: In a home energy audit, its sensitivity can highlight the faint cool signatures of air infiltration around window frames or electrical outlets. The resolution helps distinguish between a small draft and a larger insulation void in the attic. Radiometric data allows quantifying the temperature difference, potentially helping estimate energy loss.

- The Electrical Guardian: Scanning an electrical panel (from a safe distance!), the camera’s range can handle normal operating temperatures, while its accuracy helps determine if a breaker reading $150^{\circ}$F ($65^{\circ}$C) is truly running hot. High resolution helps pinpoint which connection or wire is the source of the heat, preventing unnecessary replacement of entire components. Overheating due to high resistance in a poor connection becomes glaringly obvious long before traditional inspection methods might reveal it.

- The HVAC Whisperer: Tracing ductwork, the sensitivity can reveal cool spots indicating leaking conditioned air into unconditioned spaces like crawlspaces. The temperature range allows checking both the cooling coils and heating elements. Video recording might capture intermittent issues or demonstrate airflow patterns over time.

The inclusion of a standard Visible Light Camera is also invaluable. Often, thermal images alone can be disorienting. Seeing the corresponding visible light image, or perhaps a blended “picture-in-picture” view, provides crucial context for precisely locating the thermal anomaly in the physical world. Video Recording further enhances documentation, allowing for dynamic assessment of heating/cooling cycles or capturing findings during a walk-through inspection.

Connectivity and Interface: Modern Conveniences

Features like WiFi connectivity and an underlying Android Operating System (as mentioned in the source) suggest a modern device architecture. WiFi could potentially enable convenient firmware updates directly on the device, ensuring access to the latest features or performance improvements. The source also mentions the ability to livestream the camera’s view to a computer, which could be useful for collaborative diagnostics or viewing images on a much larger screen for detailed scrutiny. A Touch Screen interface typically simplifies navigation and allows for intuitive interaction, such as tapping on a point in the image to get an immediate temperature reading.

Seeing Clearly: Understanding Limitations

As powerful as thermal imaging is, it’s not X-ray vision. It’s essential to understand its limitations for effective use:

- Surface Temperatures Only: Thermal imagers measure the temperature of an object’s surface. They cannot see “through” solid objects like walls (though temperature differences on the wall surface can indicate what’s happening behind it, like a hot pipe or missing insulation).

- Emissivity Matters: As mentioned, accurately measuring temperature requires accounting for the emissivity of the surface. Shiny, reflective surfaces are particularly challenging as they reflect the IR energy from their surroundings, potentially misleading the camera.

- Reflections Can Confuse: Just like visible light, IR can reflect off surfaces. A “hot spot” seen on a smooth floor might actually be a reflection from a ceiling light fixture. Careful interpretation is needed.

- Environmental Factors: Wind (convective cooling) and direct sunlight (solar loading) can significantly alter surface temperatures, potentially masking or exaggerating underlying thermal patterns.

Understanding these limitations prevents misinterpretation and ensures the technology is used effectively.

Conclusion: Empowered by a New Way of Seeing

From Sir William Herschel’s serendipitous discovery to sophisticated handheld devices like the PerfectPrime IR281, our ability to perceive and interpret the infrared world has profoundly expanded our understanding. Thermal imaging pierces the veil of the visible, revealing a dynamic landscape of heat flow, energy exchange, and potential problems hidden from our unaided senses.

Tools like the IR281, equipped with specifications like $206 \times 156$ pixel resolution, a broad $-40^{\circ}$F to $626^{\circ}$F temperature range, critical $0.065^{\circ}$C sensitivity, and the analytical depth of radiometric data capture, don’t just show us pictures; they offer insights. They empower homeowners to find energy waste, technicians to diagnose electrical and mechanical faults proactively, and building professionals to ensure structures are safe, efficient, and comfortable.

By translating the invisible language of heat into actionable information, thermal imaging enhances our awareness and equips us to make smarter, more informed decisions. It’s a testament to how harnessing scientific principles can grant us, quite literally, a new way of seeing our world.